Introduction

For decades, activated carbon was often treated as a simple commodity – interchangeable, price-driven, and evaluated primarily by a small set of basic parameters. In many markets, purchasing decisions focused on availability and cost rather than application performance.

Today, that perception is rapidly changing. Across industries, activated carbon is increasingly recognized as a functional engineering material whose performance depends on application-specific design, process compatibility, and long-term stability.

The Limits of a Commodity Mindset

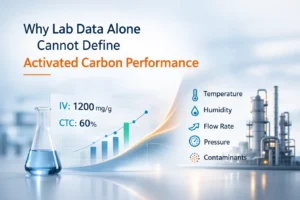

The traditional commodity approach assumes that activated carbon with similar specifications will deliver similar results. In practice, this assumption frequently fails.

Industries ranging from food processing to environmental protection have discovered that minor differences in raw materials, pore structure, and surface chemistry can lead to significant performance variation in real operating conditions.

Application-Driven Performance Requirements

Modern industrial systems place increasingly precise demands on activated carbon. Adsorption efficiency alone is no longer sufficient.

Different applications require different performance priorities – such as mass transfer rate, impurity selectivity, mechanical strength, or regeneration stability. As a result, activated carbon must be designed to match specific process conditions rather than generic test values. At HANYAN, we have consistently focused on the development and production of activated carbon solutions tailored to the specific requirements of different industries, rather than relying on one-size-fits-all materials.

Regulation, Safety, and Consistency

Stricter regulatory frameworks have also reshaped expectations. In food, pharmaceutical, and environmental applications, material traceability, impurity control, and compliance with safety standards are now essential.

This shift has elevated the importance of production consistency and quality management systems. Activated carbon is no longer judged solely by initial performance, but by its reliability over extended operational cycles.

From Adsorbent to Process Component

As industrial processes become more integrated and optimized, activated carbon increasingly functions as a critical process component rather than an auxiliary material.

In many systems, activated carbon performance directly influences downstream efficiency, product quality, and operating costs. This has encouraged closer collaboration between carbon manufacturers, system designers, and end users.

Why Price Alone Is No Longer Enough

While cost remains a factor, it is no longer the dominant decision criterion. Low-cost materials that fail to deliver stable performance often result in higher overall operating expenses through reduced efficiency, frequent replacement, or process disruption.

As a result, industrial users are shifting their focus toward total performance value rather than unit price.

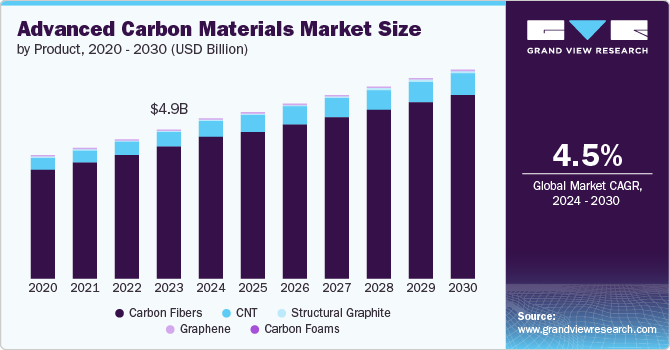

The Future of the Activated Carbon Industry

The evolution of activated carbon from commodity to engineered material reflects broader trends in industrial manufacturing. Customization, application knowledge, and performance consistency are becoming key differentiators.

Companies that invest in material science, process understanding, and quality control are better positioned to support complex industrial applications in a rapidly changing market.

Conclusion

Activated carbon is no longer a one-size-fits-all material. Its role in modern industry has expanded from basic adsorption to a performance-critical function within complex systems.

Recognizing activated carbon as an engineered material rather than a commodity is essential for achieving reliable, efficient, and sustainable industrial processes.

Article keywords: activated carbon industry trends, activated carbon applications, engineered activated carbon, industrial adsorption materials, activated carbon performance evaluation