Introduction

Activated carbon has evolved far beyond its traditional role as a basic adsorbent. In modern industrial systems, it functions as a performance enabler, supporting purification, decolorization, separation, emission control, and process stabilization across multiple sectors.

Driven by stricter environmental regulations, higher product purity standards, and continuous industrial upgrading, global demand for high-performance activated carbon continues to grow. Understanding how activated carbon works, where it is applied, and what determines its performance is essential for industrial users worldwide.

What Is Activated Carbon?

Activated carbon is a porous carbonaceous material produced through controlled carbonization and activation processes. Its internal pore structure – comprising micropores, mesopores, and macropores – provides a large specific surface area, enabling efficient adsorption of gases, vapors, and dissolved substances.

Depending on raw materials and activation methods, activated carbon can be manufactured in various forms, including granular, powdered, pelletized, and engineered structures tailored for industrial use.

Key Industrial Applications of Activated Carbon

Activated carbon plays a critical role across a wide range of industries, each with different technical requirements and performance expectations.

| Industry | Typical Applications |

|---|---|

| Food & Beverage | Decolorization, deodorization, impurity removal |

| Pharmaceuticals | API purification, solvent recovery |

| Chemical Processing | Catalyst protection, by-product adsorption |

| Environmental Engineering | Air emission control, water treatment |

| Energy & New Materials | Gas purification, specialty carbon materials |

Factors That Determine Activated Carbon Performance

Pore Structure Distribution

Micropores primarily determine adsorption capacity, while mesopores improve mass transfer efficiency. Macropores support fluid flow and ensure accessibility of internal surfaces.

Surface Chemistry

Surface functional groups influence adsorption selectivity, chemical stability, and interaction with specific contaminants under different operating conditions.

Mechanical Strength and Stability

Industrial applications often involve pressure drop, vibration, or regeneration cycles. High hardness and low attrition are essential for maintaining long-term system performance.

Process Matching

Even high-quality activated carbon may underperform if not properly matched to contact time, flow rate, temperature, and contaminant characteristics.

Global Market Trends in the Activated Carbon Industry

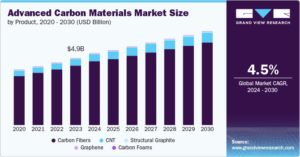

The global activated carbon market is undergoing significant transformation. Key trends include stricter environmental compliance requirements, growing demand for customized carbon solutions, and increased focus on raw material stability.

Rather than competing solely on price, leading manufacturers are investing in application-specific R&D, production consistency, and integrated filtration solutions.

Choosing the Right Activated Carbon Partner

Selecting an activated carbon supplier involves more than reviewing specification sheets. Industrial users increasingly value partners who can provide technical insight, consistent quality, and long-term supply reliability.

A reliable supplier contributes not only materials, but also experience in process optimization and application support.

Conclusion

Activated carbon remains a foundational material in modern industry, with its importance continuing to grow as regulatory standards tighten and industrial systems become more complex.

By focusing on performance drivers, proper material selection, and long-term reliability, industrial users can unlock greater value from activated carbon solutions in a wide range of applications.

Article keywords: activated carbon, industrial activated carbon, activated carbon applications, activated carbon performance, adsorption materials, activated carbon market trends, high-performance activated carbon